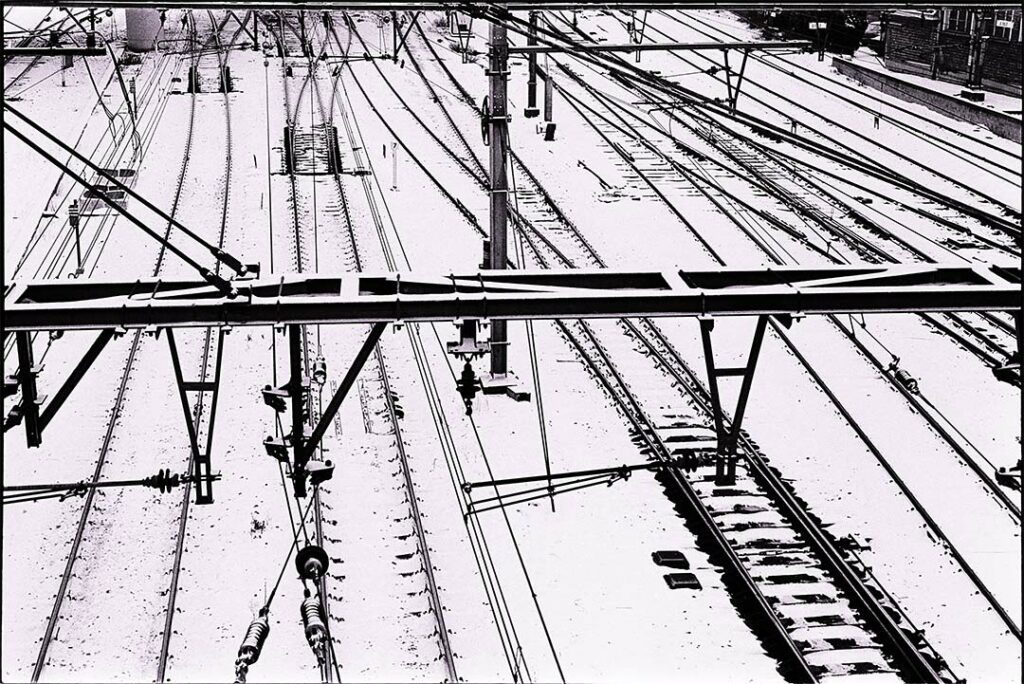

Winter weather, especially snow and ice, can pose significant challenges to railway operations. A key solution to these issues lies in the use of points heating systems. This article will delve into the importance of these systems, their operational mechanisms, and how they help in maintaining the smooth functioning of railways during harsh winter conditions.

Understanding the Problem: Impact of Ice and Snow on Railway Operations

The formation of ice and snow on railway tracks can lead to a multitude of problems, potentially disrupting rail traffic and posing safety risks. Here are some key issues that can occur:

- Impediments to Point Movements: Snow can compact under passing trains, turning into solid ice, especially in areas where trains move slowly. This ice prevents the movement of points, hampering rail traffic.

- Interruption to Power Supply: In regions where a third rail is used for electrification, ice build-up can hinder power delivery to trains, leading to service disruptions.

- Signalling Issues: Rails freezing together can cause signals to stay red, halting train movement.

- Track Blockage: Heavy snowfall can cause branches to break off trees, damaging overhead wires and obstructing tracks.

- Snow Drifts: High winds can lead to snow drifts of 30 cm or more. In such cases, trains must be fitted with snow ploughs for safe operation.

The Solution: Points Heating System

A points heating system provides an effective solution to these problems. They are designed to prevent the formation of ice and snow on points from the heat generated, ensuring their smooth operation even in harsh winter conditions.

An Insight into the Working Mechanism

Points heating systems use heaters attached to points to melt any snow or ice that may accumulate. These heaters are controlled by specially designed control cubicles, ensuring efficient operation and energy usage. In addition to the heaters, protective covers are also installed on points and points motors to keep out snow.

The operation of points heating systems involves sophisticated technology and meticulous planning. Various sensors and thermostats are used to monitor temperature conditions. When temperatures drop below a certain level, the heating systems are automatically activated, preventing the build-up of ice and snow.

Heating Control Cubicles: The Brain of the System

Points heating control cubicles play a crucial role in the functioning of points heating systems. It houses the control equipment necessary for the operation of the heaters. The heating control cubicles, monitor temperature and snowfall conditions, activating and deactivating the heaters as required.

The heating control cubicles are designed to be robust and weatherproof, capable of withstanding harsh winter conditions. It ensures that the heaters function optimally, providing effective ice and snow melting capabilities while minimising energy usage.

Preparing for Winter: The Importance of Proactive Measures

Efficient operation of points heating systems requires proactive planning and preparation. This includes ensuring that the track is clear of obstructions, such as overhanging snow-laden vegetation or icicles at tunnel entrances. Spare parts should be readily available at key locations for assets sensitive to ice and snow. Additionally, fences are installed on major routes to prevent snow from blowing onto the tracks.

Monitoring and Response: Ensuring Smooth Operation

Close monitoring of weather conditions and appropriate response measures are vital for the effective functioning of points heating systems. Weather experts discuss with route teams the actions to be taken based on weather forecasts. This could include introducing temporary speed restrictions, sending staff to monitor at-risk assets, or sending patrols to remove ice from overhead lines. In extreme cases, line closures may be necessary while heavy snow is being cleared.

The Role of Technology: Snow and Ice Treatment Trains

In addition to points heating systems, technology plays a crucial role in combating winter weather challenges. Snow and Ice Treatment Trains, part of the dedicated fleet of machines, are ready at depots across the country, ready to be deployed whenever ice and snow are forecast. These trains are equipped with high-powered jets to spray heated anti-freeze onto the conductor rail, helping to prevent ice from forming.

Embracing Winter Challenges: Towards a Resilient Railway System

Point Heaters, along with other technological solutions, play a pivotal role in ensuring the resilience of railway operations in the face of winter weather challenges. By preventing the accumulation of ice and snow on tracks, they not only ensure the smooth operation of trains but also enhance the safety of railway operations.

Moreover, the use of points heating systems reflects the railway industry’s commitment to providing reliable and uninterrupted service, regardless of weather conditions. It is a testament to the industry’s capability to embrace challenges and leverage technology to overcome them.

Winter weather, with its potential to disrupt railway operations, presents a significant challenge to the railway industry. However, with the use of points heating systems and other technological solutions, the industry is well-equipped to face this challenge and ensure the smooth and safe operation of trains, even in the harshest winter conditions.